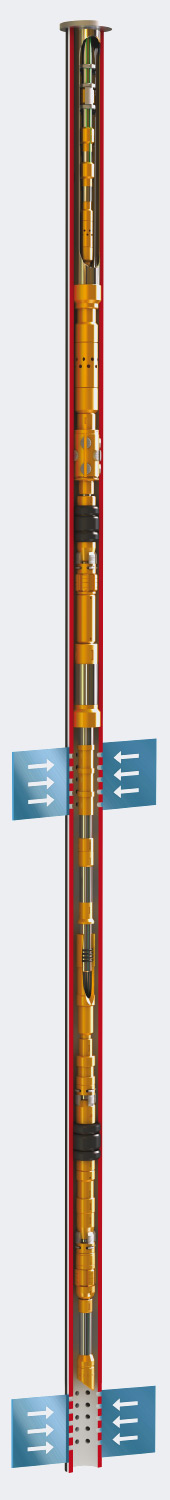

Equipment Kit KOUS-DPK-DLK-ORE

Benefits

- Allows independent metering of produced gas;

- Enables dual injection of corrosion or hydrate inhibitors through chemical injection valves;

- Provides temporary communication between the annulus and each of the tubing strings;

Components

- Chemical injection mandrels KI;

- Circulating subs KCP;

- Axial mechanical set packer PM-R;

- Axial mechanical set packer PVM-O (F);

- On-off sealing connector RK-S (U);

- Release joint P-B;

- Re-entry guide V;

- Re-entry guide with a pumpout plug.

* Differential pressure ratings — 7252 psi; 10150 psi.

Working temperature ratings 266 °F, 302 °F, 338 °F.

Higher performance assembly available for hostile environments - K2 Model.

Optional premium gas-proof threads are available on request.

Other sizes of the assembly are available on request.